syringe friction force test

Glide Force Testing for Syringes

Ensure syringe safety with precise glide force testing.

About Us

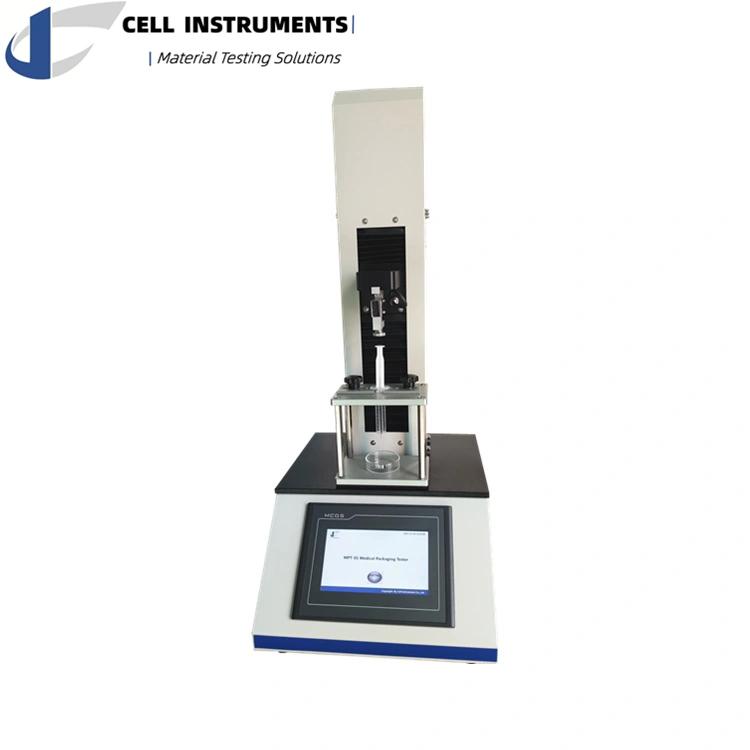

Medical Syringe Tester

Glide force testing is a critical procedure in ensuring the safety, reliability, and comfort of syringes and injectable devices. By accurately measuring break loose force and glide force, manufacturers can comply with international standards such as USP 382, ISO 11040-4, ISO 7886-1, ISO 8537, and ISO 11608-5, while guaranteeing consistent product performance. Our advanced syringe glide force testing solutions provide precise, repeatable results to support regulatory approval and patient safety.

Specification

| Test Range | 30N, 50N~500N, etc. |

| Stroke | 200mm (without stroke) |

| Accuracy | 0.5% F.S., 0.01mm |

| Display | 7 inch color HMI touch screen |

| Control | PLC |

| Power | AC 110~220V 50/60Hz |

Technical Features

- PLC control with 7 – inch touch – screen HMI for streamlined operation and user – defined test programming

- Precision ball – screw drive ensuring consistent speed and displacement control (1 – 500 mm/min).

- Modular fixtures to accommodate various syringe and needle tests.

- Safety features: position restrictor, overload and over – travel protection, and automatic return to start position after each test.

- Built – in microprinter, with optional RS – 232 and PC software for data export and traceability.

- High accuracy: ±0.5% full scale, 0.01 mm resolution, stroke up to 200 mm, force range nominally 50 N – 500N (customizable)

- Access level setting and test data storage, to satisfy GMP and CFR 21 regulations

Syringe Quality Control Testing

Product Introduction

– Precision Glide Force Testing Solutions

1.High-Accuracy Glide Force Measurement

Our advanced testing systems are designed to accurately measure glide force and break loose force in syringes, auto-injectors, and prefilled systems. Ensuring consistent performance is vital for patient safety and device reliability.

2.Comprehensive Syringe Glide Force Testing

From ISO 11040-4 glass syringes to ISO 7886-1 disposable syringes, our instruments support a wide range of syringe types. Each device can be tested for break loose force and glide force to ensure compliance with strict industry standards.

3.Compatible with Multiple Syringe Formats

Whether you are testing ISO 8537 insulin syringes, prefilled syringes, or custom devices, our testers adapt to your product line. Specialized jigs and fixtures guarantee stable, repeatable measurements.

3.Automated and User-Friendly Operation

Our systems streamline syringe glide force testing with automated measurement, digital data output, and real-time analysis. This minimizes human error and speeds up quality control processes.

Add Your Heading Text Here

Standards Emphasis – Complying with Global Regulations

| Standard | Scope | Key Focus |

| USP 382 | Syringes & Prefilled Systems | Defines testing for break loose force and glide force to ensure safe, consistent performance. |

| ISO 11040-4 | Glass Syringes | Specifies requirements for glass syringes in pharmaceutical applications. |

| ISO 7886-1 | Disposable Syringes | Covers design and functional performance of single-use syringes. |

| ISO 8537 | Insulin Syringes | Establishes standards for insulin syringes with or without fixed needles. |

| ISO 11040-4 | Glass Syringes (duplicate reference) | Ensures glass syringe safety and quality in compliance with global standards. |

Importance of Glide Force and Break Loose Force Testing

Ensuring Patient Comfort and Safety

Excessive break loose force or glide force can result in patient discomfort and inconsistent drug delivery. Accurate testing ensures smooth syringe performance.

Guaranteeing Product Reliability

Reliable syringe glide force testing reduces risks of malfunction, leakage, or inconsistent dosing, which are critical in healthcare applications.

Supporting Regulatory Approval

Compliance with USP and ISO standards strengthens your product’s global acceptance and regulatory submissions.

Minimizing Manufacturing Risks

By performing break loose and glide force testing during production, manufacturers can detect defects early, reducing waste and costly recalls.

Syringe Testing According To Pharmacopoeia

Why Choose Us – Your Trusted Glide Force Testing Partner

01

Proven Expertise in Syringe Testing

With years of experience, we specialize in glide force and break loose force testing, serving leading pharmaceutical and medical device companies.

02

Advanced Technology & Precision Engineering

Our testing systems are built with high-precision load cells, ensuring accurate, repeatable, and traceable results for every test.

02

Dedicated Customer Support

From installation to training and after-sales service, our team provides comprehensive support to ensure your glide force syringe testing runs smoothly and efficiently.

The glide force tester improved our quality control with accurate, USP and ISO-compliant results. It streamlined submissions and reduced variability.

– CELL INSTRUMENTS

Frequently Asked Questions about Bekk Smoothness Test

1. What is glide force testing?

Glide force testing measures the force required to move a syringe plunger after initial break loose. It ensures smooth drug delivery and patient comfort.

2. What is break loose force?

Break loose force is the initial force needed to overcome plunger resistance in a syringe. It is tested together with glide force to evaluate syringe performance.

3. Why are glide force and break loose force important?

These tests ensure syringes function safely, consistently, and comfortably. Excessive force can cause dosage errors, leakage, or patient discomfort.

4. Which standards apply to glide force testing?

Glide force and break loose force testing follow USP 382, ISO 11040-4, ISO 7886-1, ISO 8537, and ISO 11608-5, depending on syringe type.

5. What types of syringes can be tested?

Our systems cover glass syringes, disposable syringes, insulin syringes, prefilled syringes, and auto-injectors.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985